Hello everyone. My name is Hiroyuki Oka. I’m a Japanese puzzle box craftsman. I was born in Odawara City, Japan, and have been making these puzzle boxes for over 20 years. My workshop (OKA CRAFT) is located in Odawara City. I post a blog about my production process every day from Monday to Friday (with some diary-like entries as well). The same articles are also written on my website (https://www.japanesepuzzlebox.jp), where these are transcribed. I would be delighted if you read it. Since I create each box by myself, it might take some time to restock sold-out items of my online-shop. Please be patient. Additionally, I occasionally make unique boxes that are not sold on other sites, so please check it together with this blog. Enjoy my puzzle boxes! Hiroyuki

01-Aug-2024

There is another solution to the problem of the Japanese puzzle box mechanism sticking together after finish coating. After applying the finish coats, but before the paint has completely dried, I can move the mechanism of the puzzle box once (i.e., open the puzzle box). Of course, touching the freshly painted areas will result in paint getting on my hands. This could leave fingerprints on the box, which would require repainting. It takes several hours for the paint to fully dry, roughly a whole day (24 hours). During the period when it is safe to touch the box but the paint is not yet completely dry and the mechanisms are still easy to move, I should open the puzzle box once.

There was a time when I tried this method. However, it was difficult to match the timing, and I had to stop my other work midway to open the puzzle box. If I did the coating work at the end of the day, I would have to wait for it to start drying. Additionally, even after opening the box once, the paint would not be completely dry, and by the next day, the mechanism would sometimes stick together again (although not as much as if they had not been moved at all). Therefore, I would have to open the mechanism again in the same way.

and After trying various methods, I currently move the mechanism once after the base coat has completely dried. Then, after the finish coat has completely dried, I open the puzzle box to check the movement of the mechanism.

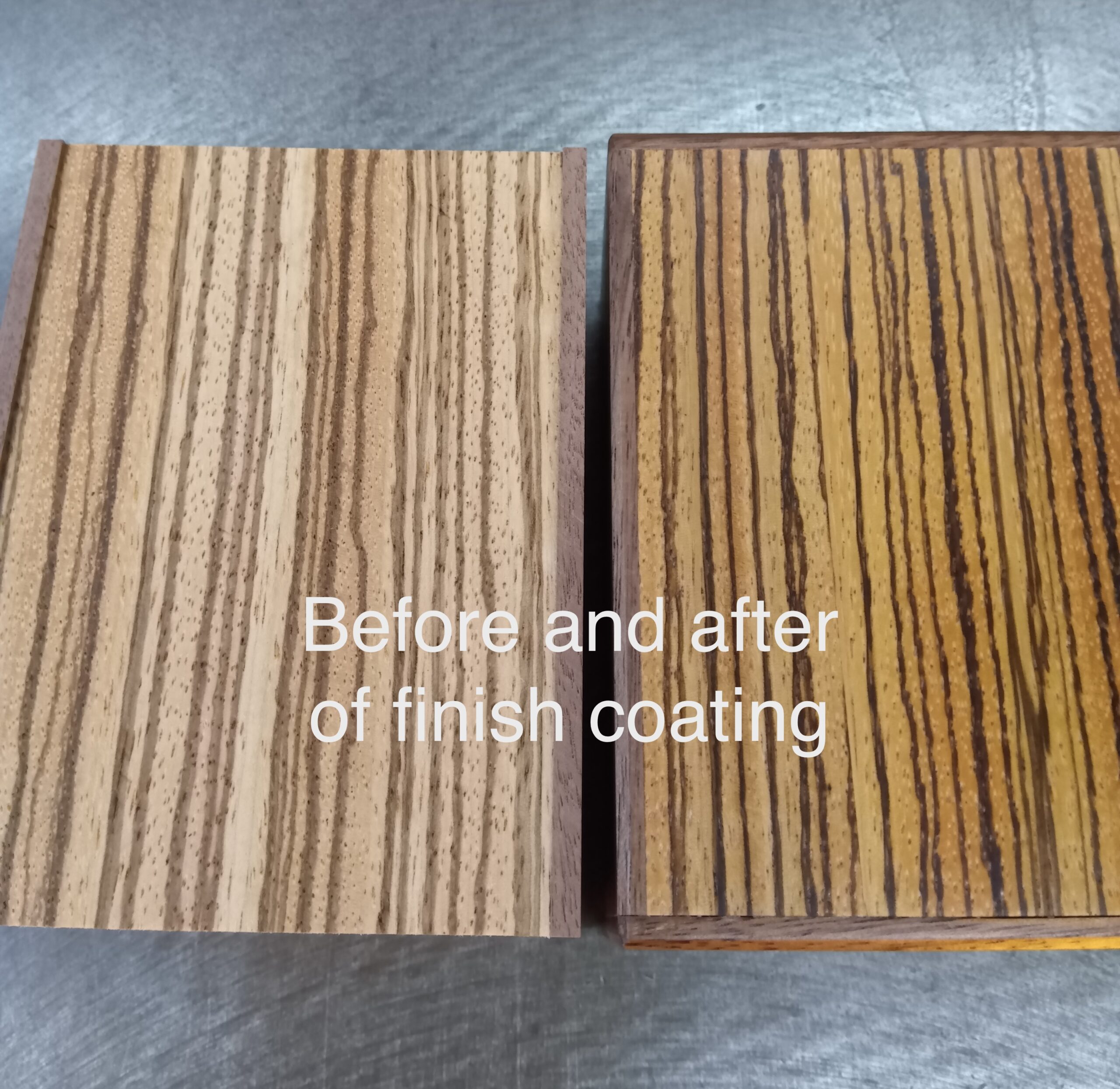

If I make the paint layer thicker, the puzzle box will shine more brilliantly! However, the mechanism will stick together more, and it would take a large hammer to open it!🤣 In this way, there is a relationship between the number of finish coats, that is, the thickness of the paint layer, and the degree to which the mechanism stick together. Therefore, the paint on Japanese puzzle boxes is relatively thin. However, thin paint makes the internal components more susceptible to external conditions such as humidity and temperature, so in reality, a thicker paint layer would be better. It’s quite a tricky problem.

The Japanese puzzle boxes have a history of about 100 years, but the plastic-based paints we currently use (urethane paints) have only been used recently. In the past, there were paints made from natural tree sap, so they probably used those….Actually, the puzzle boxes in the old days were painted using a certain method, and that method was….