I worked in the workshop again from the morning today. But since it is Saturday, the pace is a little slower than usual. Instead of pushing forward quickly, I often use this time to adjust and check the work I did during the week. For example, today I found that two of the puzzle boxes with drawers that had already finished the painting stage needed a small correction. So I fixed them and will apply the finish once again. This kind of thing happens from time to time, and it is not easy to complete everything perfectly in just one step.

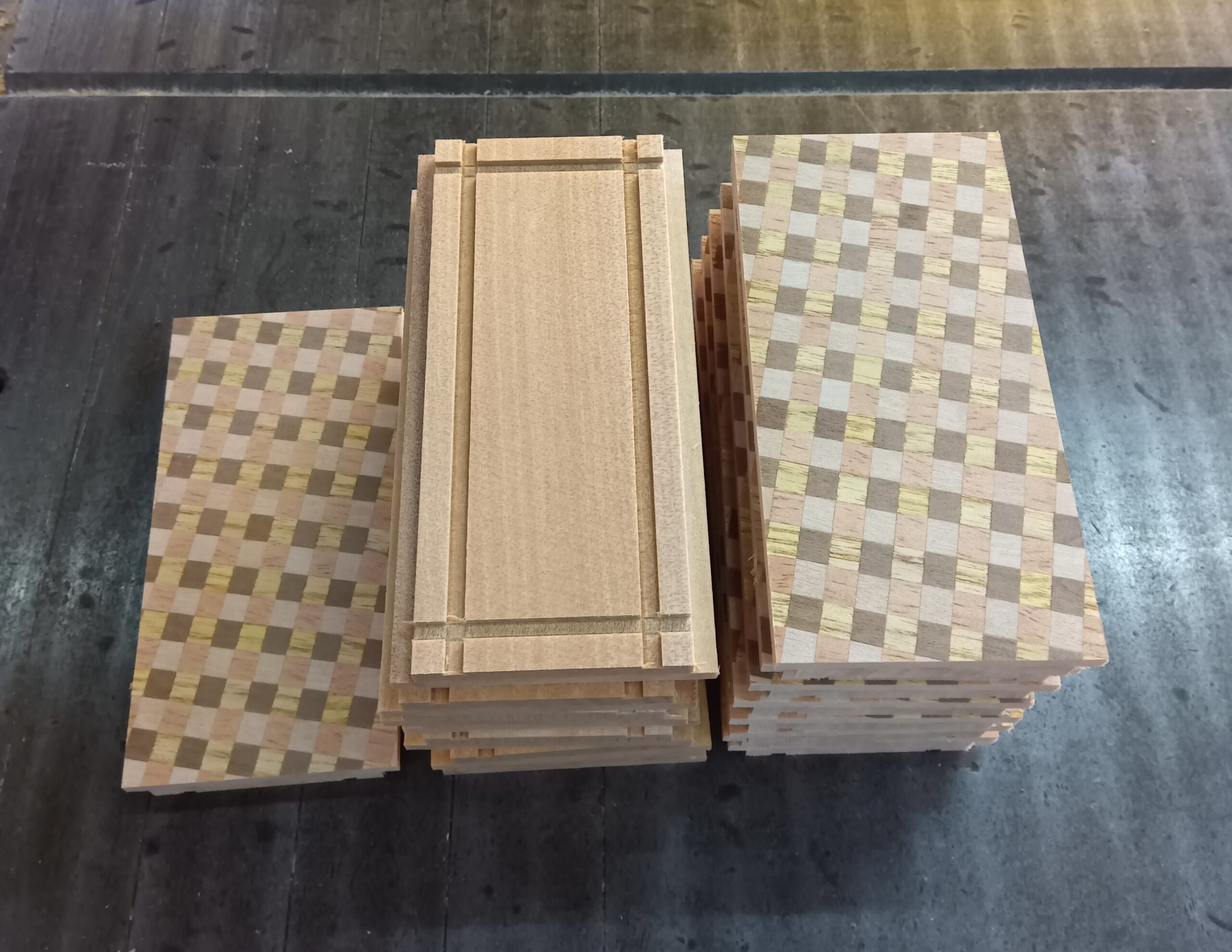

While doing those adjustments, I also worked on the next project today, which is the 4-sun 27-steps puzzle boxes. I processed the side panels for these boxes. The boards had already been shaved down to the correct thickness and prepared in advance, and from those boards I made the side panels of the boxes, as shown in the photo. I cut them to size and carved grooves in four places. The Aruki panels slide along these grooves. This time, since it is a 27-steps puzzle box, the Aruki panels are 8.5 mm thick, so the grooves are made slightly wider, at 3 mm. I choose the width of the grooves so that it balances well with the thickness of the Aruki panels. At the moment, I am not making any boxes with thicker Aruki panels than this, so 3 mm is the widest groove I use. In the past, I made puzzle boxes with a much higher number of steps, such as 66-steps and 78-steps puzzle boxes. For those, I used thicker Aruki panels and wider grooves to match. In recent years, the highest number of steps I have made is 54. So I still use the same 3 mm grooves. Although 54 steps is a high number, I do not increase the thickness of the Aruki panels to make the mechanism go around few more full cycle. Instead, I increase the number of sliding keys to raise the total number of steps. That is why the thickness of the Aruki panels remains the same at 8.5 mm. In this way, I finished the processing safely, and the side panels I made are now stacked again and pressed with clamps. The materials for puzzle boxes are very sensitive to warping, so I try to prevent that by pressing them with clamps like this, or by placing a board on top of the stacked panels and adding weights.

This time, about 50 of the 27-steps puzzle boxes are already ordered, but I will make a few extra, so I am thinking about what designs to choose. For now, I plan to make a few in the “random grain” style that I made last year. Since one of the ordered boxes uses zebrawood for the top and bottom panels, I am also thinking of making a few extra with zebrawood. Recently, I often use walnut, zebrawood, or rosewood for the top and bottom panels. Somewhat surprisingly, zebrawood is quite popular. Maybe its bold and unique appearance appeals to people. This time, I purchased the sliced wood sheets newly from a supplier who specializes in sliced wood veneer.

Today, the highest temperature was around 14 degrees Celsius, so it felt fairly warm. Tomorrow, it is supposed to be even warmer ☀️